Tsarin samarwa na roba roba gaba daya yana bin matakai da yawa, gami da shirye-shiryen kayan roba, gyare-jita na roba, rashin ƙarfi na rollers roba, da jiyya na roba. Ya zuwa yanzu, yawancin masana'antar har yanzu suna dogara ne akan tsarin haɓaka keɓaɓɓen naúrar. A cikin 'yan shekarun nan, tare da ci gaba da ci gaba na allura, cirewa, da fasahar ruwa, roba mai amfani da roba mai narkewa a kan layin da ke tattarawa a kan layi. Don haka, ci gaba da samar da kayan roba zuwa ga kayan roba zuwa gunaguni da ingantaccen aiki kuma inganta yanayin aiki da ƙarfin aiki. Saboda babu wani abu mai ban sha'awa, ramuka na yashi, da kumfa a kan roba saman roba, lahani, cracks, ko bambance-bambance a cikin wuya. Sabili da haka, ta hanyar ajiye roba mai tsabta sosai kuma an tsara shi a duk faɗin tsarin samarwa, an cimma nasarar haɗin kai da daidaitattun fasaha na samfuran da aka haɗa, na iya ba da tabbacin samfuran da aka tsara. A halin yanzu, haɗuwa, haɗin, allurar rigakafi, rashin daidaituwa da kuma niƙa na roba da ƙarfe na ƙarfe sun zama matakan fasaha.

Shiri na kayan roba don tsarin samar da roba

Don roba mai roba, cakuda kayan roba shine mafi mahimmancin mataki. Akwai nau'ikan kayan roba sama da 10 da aka yi amfani da su don roba mai roba, da kuma irin roba na roba na 255% da wuya digiri, spanning da wuya. Hanyar al'ada ita ce amfani da na'urar haɗe ta roba don haɗawa da aiwatar da nau'ikan nau'ikan ƙwayoyin dabbobi. Da abin da ake kira injin hadewar roba wani nau'in kayan masarufi ne tare da fallasa rollers da aka yi amfani da shi a cikin masana'antar roba don shirya roba gauraye, ma'aurata ma'aurata,Filastik filastik, da kuma gyaran kayan masarufi. Koyaya, waɗannan nau'ikan kayan aikin filastik ne. A cikin 'yan shekarun nan, masana'antu sun ƙara sauya don amfani da tsawan cututtukan ciki don samar da kayan roba ta hanyar haɗawa.

Bayan cin nasarar hadawa na uniform, kayan roba yana buƙatar tace ta amfani da injin tace rani don kawar da ƙwararrun mashin a cikin kayan roba. Sannan yi amfani da ASTER, EXPSONATE, da na'ura Lamining don yin fim ko tsiri ba tare da kumfa ko impurities, wanda ake amfani da shi don samar da rollers roba. Kafin forming, mai tsayayyen bincike na gani ya kamata a za'ayi akan waɗannan fina-finai da tube roba, kuma ya kamata a sa rigar sabo don hana adhesion da ƙirar ƙira. A saman roba roba da ya kamata ba ya ƙunshi ƙazanta da kumfa, in ba na ramuka na yashi na iya bayyana lokacin da yake nika.

Roba mai narkewa a cikin masana'antar roba rollers

Mold na roba roba yakan ƙunshi manne da roba a kan ƙarfe na ƙarfe. Hanyoyin gama gari sun haɗa da sutura, iska, gyada, allurar rigakafi, da allurar rigakafi. A halin yanzu, yawancin masana'antar gida galibi suna dogara da injiniya ko jagora tare da haɗin gwiwa, yayin da yawancin ƙasashen waje sun sami kayan aikin injin. Manyan masana'antu da matsakaitan masana'antu masu matsakaici suna ɗaukar hanyar ficewa, ta amfani da fim ɗin da aka ɗora don ci gaba da kunnawa da ƙuruciya na roba don ci gaba da samarwa. A lokaci guda, yayin aiwatar da daidaitawar tsari, ƙayyadaddun bayanai, da kuma kamannin bayyanar canzawa ta hanyar microcomputer, mai sanyawa China,Kuma ana iya sarrafa wasu ta hanyar amfani da kusurwar dama da kuma hanyoyin ɓoyewa na rashin daidaituwa.

Amfani da kwaikwayon kwaikwayon da Microgputeryy hanyoyin sarrafa kai tsaye zai iya kawar da yuwuwar kumfa da kuma rage aiki mai tsananin ƙarfi ga mafi yawan yiwuwar. Don hana nakasarwa a lokacin da m na m roba roba da hana ƙarni na kumfa da soso, Hina roba corler al'ada,Hakanan za'a iya amfani da hanyar matsin lamba mai sauƙin canzawa a waje don ingantaccen tsari na hanyar rufewa. Yawancin lokaci, yadudduka da yawa na auduga ko nailan suna kewaye da farfajiya na roba mai roba, roba roba naúrar,sannan a tsaya da gugaura tare da waya ko igiya taber.

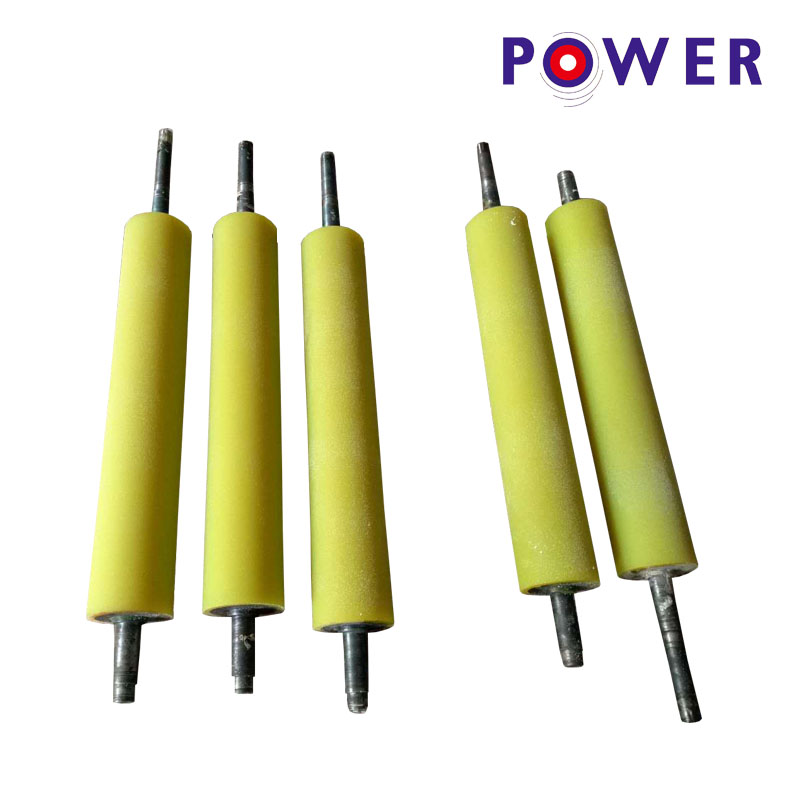

Ga ƙananan rollers da micro rumbers, matakai daban-daban na samarwa kamar patching, allurar rigakafi, allurar rigakafi, da zuba za a iya amfani da su. Don inganta ingancin samarwa, ana amfani da hanyoyin da aka gyara da aka sarrafa. Allura da latsa kan roba mai ƙarfi, da kuma zubar da roba ruwa, sun zama mafi mahimmancin samarwa.

Lokaci: Jul-25-2024