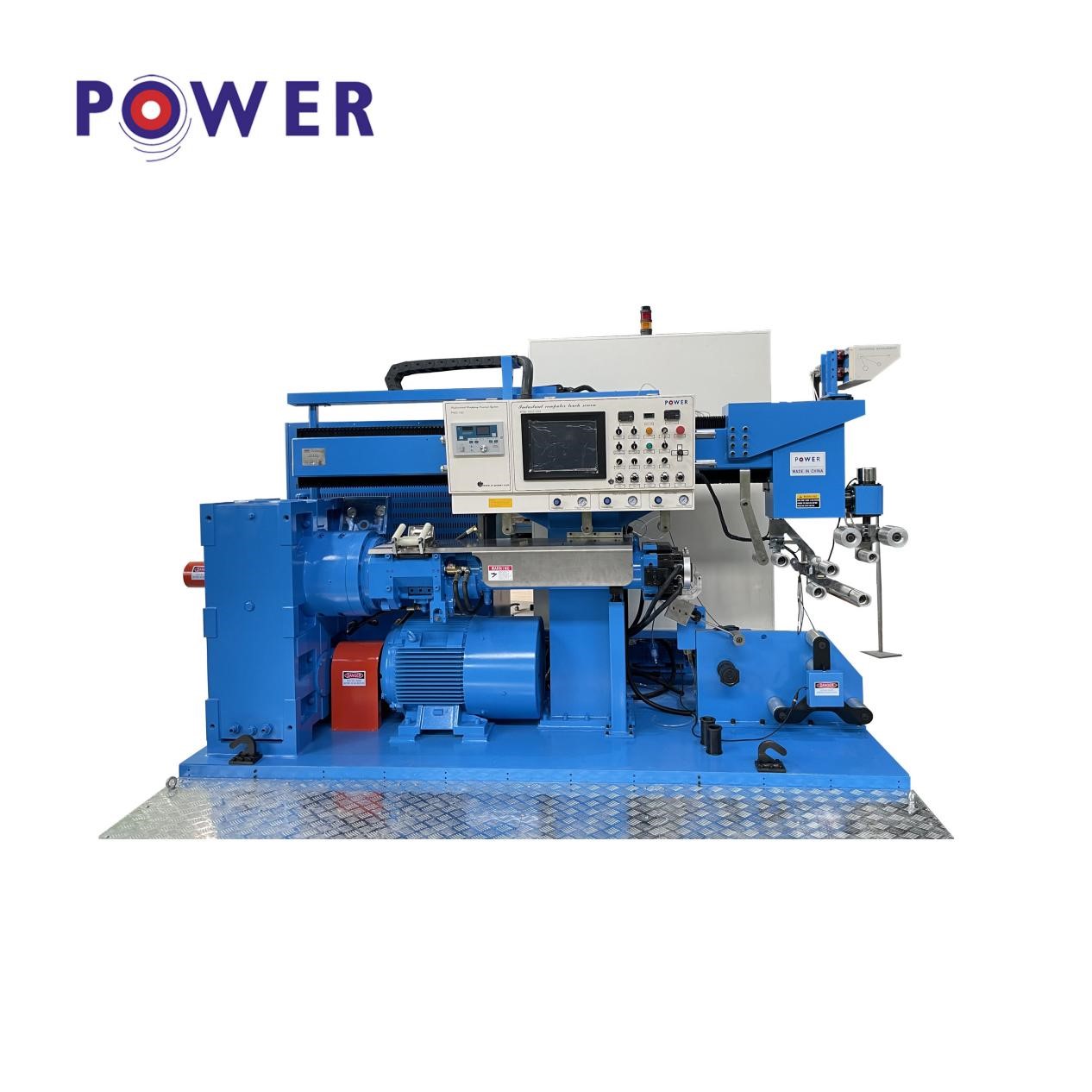

Injin rani na roba na roba shine kayan aikin da aka haɗa ta atomatik don rufewa da masana'antar roba, wanda ke inganta samfuran samarwa na roba. Kayan aiki ne na injin don jijiyoyin ruwa ta atomatik da kuma rufe roba a cikin sarrafa roba.

Injin rani na roba na roba shine kayan aikin da aka haɗa ta atomatik don rufewa da masana'antar roba, wanda ke inganta samfuran samarwa na roba. Kayan aiki ne na injin don jijiyoyin ruwa ta atomatik da kuma rufe roba a cikin sarrafa roba.

1. Sunan suna

Mene ne mashin roba roba? Wannan kayan aikin wani irin kayan aiki ne don samar da cots na roba, wanda ke amfani da mai ƙonewa don fitar da fim ɗin tsallake da kuma takaici da kuma faɗakarwa. Injin na roba mai iska ba zai iya inganta ingancin roba ba na ƙwanƙwannin roba, shafa matsalar kayan aiki da takamaiman kayan aiki da takamaiman kayan aikin roba. Tana da babban fata da amincewa abokin ciniki.

2. Bukatun Aikace-aikace

Tsarin samarwa na roba na roba yawanci yana kunshe da manyan hanyoyin sarrafawa uku: Roba Rana, rakka na roba mirgine, da jiyya na samaniya. Rangon rani na rakiyar rani wani muhimmin farawa ne farkon farawa, wanda shine tsari na rufe tauraron dany din karfe tare da roba. Idan akwai matsala a wannan hanyar haɗin, rakumi na roba da wuya a iya biyan bukatun da ake tsammanin. Tare da ci gaban masu tayar da ke cikin gida, allurar rigakafi da sauran fasahohin, layin samar da Cots ya fara aiki a kan hanyar kayan aiki da aiki da kai. Saboda buƙatun daban-daban don cots, akwai wasu imurities, ramuka na yashi, da lahani da kuma bukatun Cots ɗin haɗin yanar gizo suna ƙara tsaurara. Aikin aikace-aikacen kasuwa na injin iska mai iska ya goyi bayan nufin cimma saurin sauti, ingantaccen ƙarfi, wanda ya sami isasshen ƙarfin aiki da sauran wasanni.

3. Aiki na aiki

Saukaka ƙarshen ƙarshen maƙarƙashiyar da za a mai da hankali a kan mujami ta yi a kan kan gado na roba na iska, kuma an ƙarfafa shi ta ɗaya a ƙarshen gadonta. Lokacin da rakiyar roba cibiya a nannade, fara kwanciya ta farko, kuma mujamu uku ta fara motsawa cikin motsi daidai, yayin da aka fitar da Core Core. A kan aiwatar da ƙarancin juyawa na Roll Core, fara ƙirar roba mai ɗorewa ta hanyar jigilar roba ta hanzari ta hanyar fara iska da rufe roba. Tsarin iska mai roller core tare da m tef shi ne ainihin sakamakon haɗuwa biyu.

Idan tsiri na roba tare da wani nisa da kuma kauri mai saurin juyawa a cikin madaidaiciyar hanya tare da xxis, tsararren roba zai tsaya a kan hanyar da za a yi. A daban-daban kauri na rakiyar roba za a iya cimma ta ciyar da roba roba roliyar iska tare da y axis (roba ta fitar da shugabanci na rani).

Don saduwa da rakodin kaurin da ake bukata don iska da rani na roba dole ne a sarrafa shi, shine, adadin da aka kera roba da tsiri. Babban adadin da aka mamaye, kauri mai kauri, da kuma karami da adadin overlap, bakin ciki mai kauri. Fassarar fassarar injin iska kai tsaye yana tantance girman adadin da aka mamaye dangane da saurin juyawa na Boore.

4. Abubuwan kayan aiki

Babban abubuwan da aka haɗa na PTM Roller inji sun hada da: dandamali ciyar da roba mai ruwa, da kuma na'urar iska, roba mai iska, da kuma motar ƙarfin kayan aiki.

(1) Ciyarwar ruwan sanyi wanda aka yi amfani da shi don shirya tube roba tare da wani ƙarshen ƙarshen don yin ɗakunan roba. An nuna shi ta cewa an ƙara fitowar roba ba tare da narkewa ba, da kuma yawan zafin jiki na ƙasa yana da ƙasa, ƙwayoyin sinadarin roba yana da ƙarfi, da kuma yawan amfani da roba.

(2) A lokacin yin iska da roba na roba, dandamalin tafiya zai motsa a cikin layi madaidaiciya tare da radial hanya za a sarrafa shi. Motar Servo ce ta kori da direban Servo da saurin sauri da daidaitaccen iko.

(3) Mallaka na'urori mai manne ne ainihin ɓangaren ɓangaren roba na injin iska. Ba wai kawai ya rufe bakin murabba'in roba ba, har ma yana rufe ƙarshen fuskar roba na roba. Lokacin da na'urar iska take motsawa tare da axis Core har zuwa ƙarshen fuskar mai iska don daidaitawa zuwa ga wuri daya zuwa cikin murfin shafi don fara aiwatar da ɗora jirgin.

(4) Hanyar isar da kayan tef ɗin ta hanyar isar da hanyar isar da tef mai ɗorewa lokacin da farfajiya ta faɗakarwa ta juye juye juye ko kuma ya kashe. Ana buƙatar ingantaccen kayan aiki ba wai kawai don samun damar jigilar ƙirjin adanawa ba, amma kuma don daidaita matsayin don tabbatar da cewa tef ɗin da aka karkatarwa baya karkacewa ko faɗuwa.

(5) Bye mai roller yayi kama da Layi na kwance na yau da kullun kuma an haɗa shi da tushe, jikin gado, jikin gado, waka da tsarin watsa. An shigar da muƙamu uku mud chock a kan gado, an shigar da Chuck mai motsi a ƙarshen gado don sauƙin clamping. Tsarin watsa ya ɗauki ƙafafun ƙafafun Baixian, wanda aka kora ta hanyar sarkar. An ƙara ramin ƙarfe a gadon gado da wutsiya na gado na gado, wanda aka yi amfani da shi don tallafawa robeter gado, saboda manyan diamita robeter na iya lalata gado mai roba.

Lokaci: Sat-27-2022